Thank you for your purchase of the Infinity Steam One product. To validate your warranty, please hire an electrician and plumber to complete the installation. It’s fairly easy so shouldn’t take too much time.

The generator uses 220-240 volts, single phase power. For commercial installations, it can be reconfigured to support commercial 208 volts, three phase power. Depending on your locations, your electrician will either install a three or four wire cable of suitable gauge to support the voltage and amperage. Although the three wire is more common, some electricians use four wire cabling that’s typically used for clothes dryers. Both wiring methods will work.

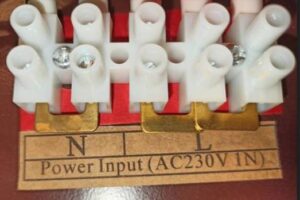

There is a single wiring block behind the front panel. Remove the panel screws to view –

If you have a three wire cable , with one wire carrying ~240 volts, one neutral and one ground, connect the 240 volt wire to the L block, the neutral wire to the N block. Do NOT remove the jumpers

If you have a four wire cable, with two wires, each supplying ~120 volts, a neutral and a ground wire, connect one ~120 volt wire to the L block and one ~120 volt wire to the N block. Do not use the neutral wire. Do NOT remove the jumpers.

In either configuration, connect the ground wire to the ground connector.

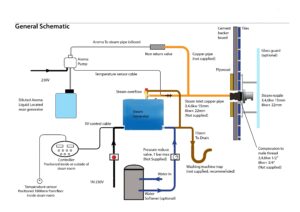

Here are some schematics to illustrate the full installation. You do not need to install the aroma pump, the descaler (typically used in commercial installations) or a light circuit to use. They are included, optional extras. You may wish to complete the basic installation and install the other components later if you wish.

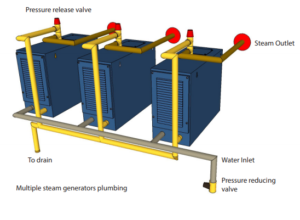

If you have a very large room, you may install multiple units and connect them together if you want for one or several rooms. Commercial customers may do this to avoid downtime if a single unit needs maintenance.

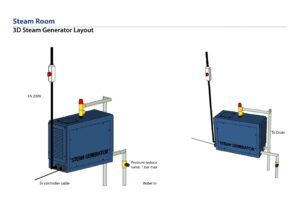

The general principal is that the generator is installed in a dry location, not subject to freezing within a reasonably short distance from the steam generator. An electrician installs a high voltage cable from a new fuse in the circuit breaker box, to the steam generator. The electrician will install a single circuit breaker box near to the generator so power can be switched off from there. The high voltage cable (sometimes called a drop) terminates at the electrical block, lower left hand corner and is usually a three wire cable connection, and sometimes four.

The plumber will install copper pipes from the steam outlets into the steam room. Be sure that these pipes do not have a “trap.” A trap is a U shape in the line where steam will condense to trap water in the pipes. That will require a higher pressure to force it out during the next use and cause a hazard.

Our generators have two steam outlets, but only one needed, especially for smaller rooms. Two steam outlets allow for reduced steam noise in the room and faster steam dispersion. Two steam outlets have better utility with higher kW generators needed for larger rooms.

In either instance, a pressure relief valve is installed to avoid generator damage is the outlet is blocked.

Water will be supplied using another copper pipe, and should have an inline emergency shutoff valve and a high volume water filter. The filter will stop water debris or particulates from entering the system and the water valve, stopping the water flow as needed.

After steam bathing, the system will automatically clean itself and drain the tank. The plumber will install a drain pipe either into the shower or into the sewer system to dispose of the waste water. Be aware that this water is very hot during the cleaning and flushing cycle.

The steam generator control is installed in the steam room and the temperature sensor is located near the ceiling. It can be installed outside, but the temperature sensor must be in the room, near the ceiling, to control the on/off steam production and maintain the desired temperature.

The optional (commercial specific) items included are an aroma oil pump, and a descaling system. The oil pump can deliver aroma oil into the steam pipe as the user requires using an automated system. Or user may also place a few drops of oil directly in the flow of steam in the room, if desired, to create a pleasant smelling aroma.

The descaling system is designed for commercial applications, where the generator may be producing steam for up to eighteen hours a day. It allows for a periodic tank deep cleaning.

This schematic shows the electrical connections. The PDF download is clearer and can be viewed here.

This is a general schematic so you can easily create the correct layout for your steam generator in installation. You can view a clearer diagram, of the image below, by downloading the PDF here.