Foreword

Thank you for choosing the Infinity Systems fragrance pump. Please spend a few moments to read these instructions before you begin, as they contain important information about the installation and maintenance requirements.

Safety Precautions

For commercial installations, ensure adequate signage to display what type of aroma is used as some users may have allergies.

Parts List

240v – 12v adapter

4 mm inlet silicone hose, six foot

4 mm outlet silicone hose, nine foot

T-junction steam pipe adapter

Temperature sensor with cable

Remote shot-of-aroma oil button

We recommend the use of steam aroma fragrance concentrates with this pump. The most common oil is Eucalyptus.

Parameters and functions

Power supply transformer:

Input voltage: 100V~240VAC

Output: 12V DC, 2W

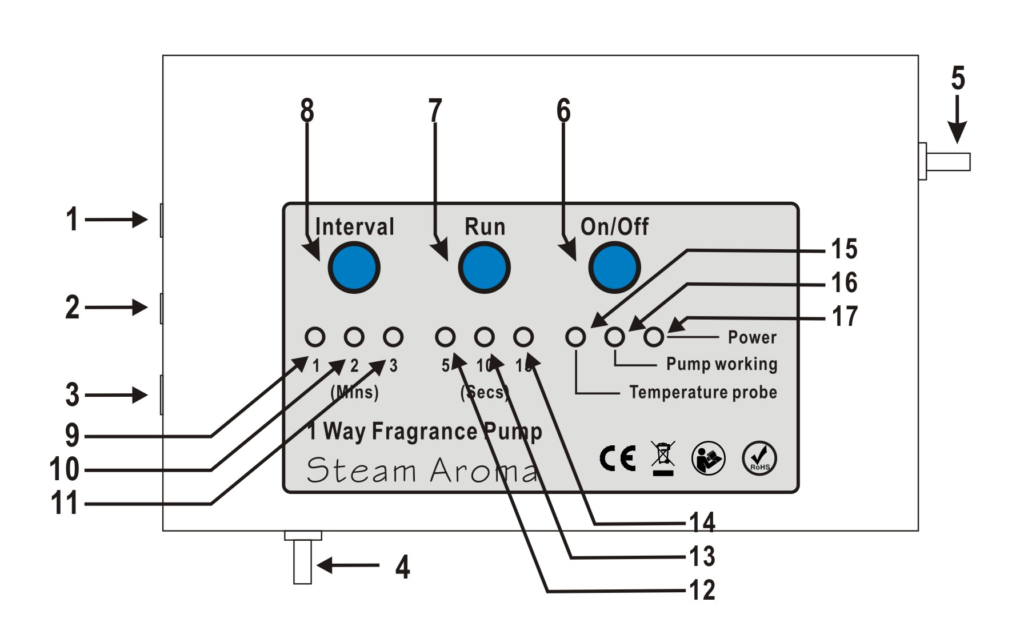

| No. | Description | Function |

| 1 | FOD | For the connection of fragrance-on-demand button |

| 2 | Temperature probe | Temperature signal input |

| 3 | Power input | 12V power supply input |

| 4 | Fragrance inlet | |

| 5 | Fragrance outlet | |

| 6 | ON/OFF key | Push to operate |

| 7 | Run Time Key | Sets the pump operating time |

| 8 | Interval Time Key | Sets the dispersal interval time |

| 9 | 1 minute interval time indicator LED | When on – pump will run every minute |

| 10 | 2 minute interval time indicator LED | When on – pump will run every 2 minutes |

| 11 | 3 minute interval time indicator LED | When on – pump will run every 3 minutes |

| 12 | 5 second running time indicator LED | When on – pump will run for 5 seconds |

| 13 | 10 second running time indicator LED | When on – pump will run for 10 seconds |

| 14 | 15 second running time indicator LED | When on – pump will run for 15 seconds |

| 15 | Temperature indicator LED | When the detected temperature on steam line achieve 185 o F, the LED is turn on and the fragrance pump will operate |

| 16 | Pump operation indicator LED | When LED is on – pump is working |

| 17 | Power indication LED | When LED is on – the power supply is okay |

Installation and operation

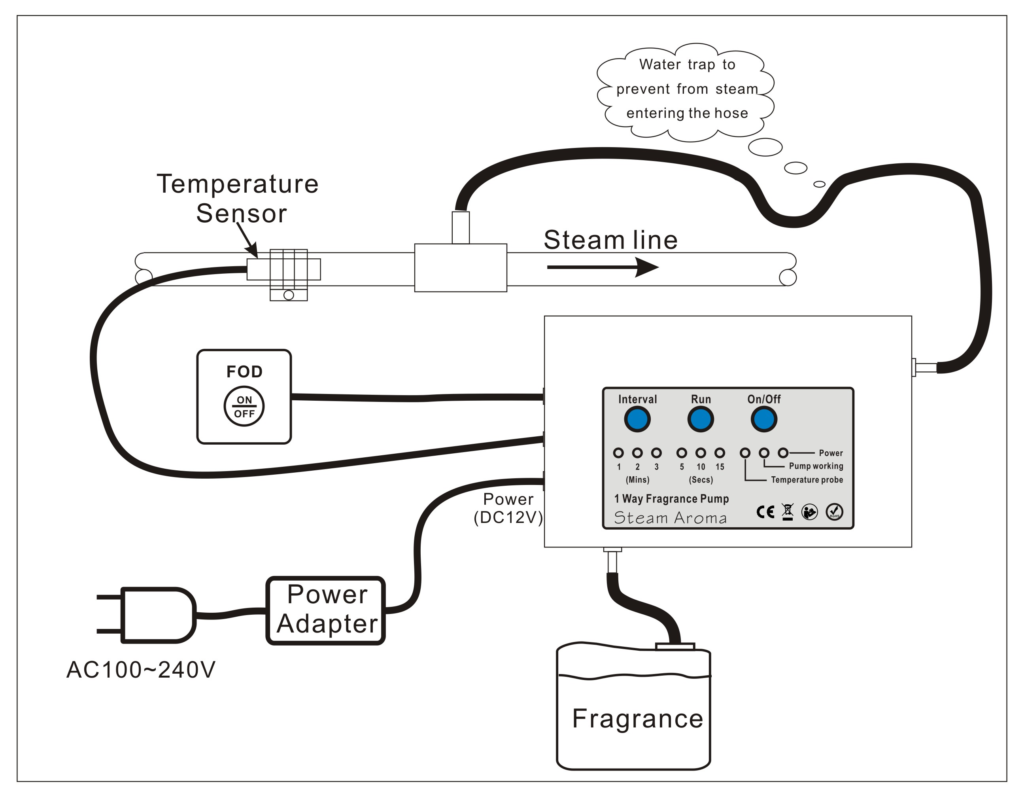

1 Install the pump in close proximity to the steam generator with a suitable power supply. The fragrance container must be no more than six feet below the pump.

2 Attach the fragrance pump onto a wall using screws and plugs.

3 Use the supplied six foot silicon hose to connect the fragrance container to the fragrance inlet port.

4 Use the supplied nine foot silicon hose to connect from the oil outlet to the steam line by inserting the 15 mm T connector as shown above.

5 Attach the temperature sensor to steam pipe using a cable tie then connect the pin into the socket on the fragrance pump.

6 Connect the adapter to the power socket and connect the adapter to power supply.

Testing and operation

This pump can be set up to work automatically – the temperature sensor is installed on the steam pipe and will only allow the pump to operate when the steam generator is producing steam. The amount of aroma oil introduced into the steam line is controlled by the RUN and INTERVAL settings.

The pump can also be controlled via a button (fragrance-on-demand) this button is water resistant and may be installed inside of the steam room. When the button is pushed, the pump will be turned on or off. This gives the option for users to choose between having aroma or not, which is obviously very useful in commercial installations where users may or may not like an aroma vapor in the steam room.

1) Fill the fragrance container with a diluted fragrance solution.

2) Turn on the power supply.

3) Press the “on/off” key so the power LED will illuminate. The default settings is to run time five seconds every one minute interval and can be changed by the operator.

4) Turn on the steam generator. When the steam line temperature reaches about 185o F the temperature indicator LED will illuminate and the pump will start to work.

5) Note that for the first operation it may require one or two operations of the pump before the fragrance enters the steam line depending upon the distance to T-connector to the steam line. Please note that the pump is self priming.

5) Depending on the size of the steam room and the concentration of fragrance required you can set the run time and interval periods to suit. Press the run button to choose the pump working time; 5 seconds, 10 seconds or 15 seconds and the relevant indicator LED will be illuminate. Press the interval button to choose the interval time – one minute, two minutes or three minutes and the relevant indicator LED will be illuminated.

The typical dilution rate of aroma concentrates is one part concentrate to twenty parts of water but you may vary this to suit user requirements – increase concentration for a more intense aroma or the opposite.

Warranty – The product has a limited warranty for twelve months from the date of purchase.

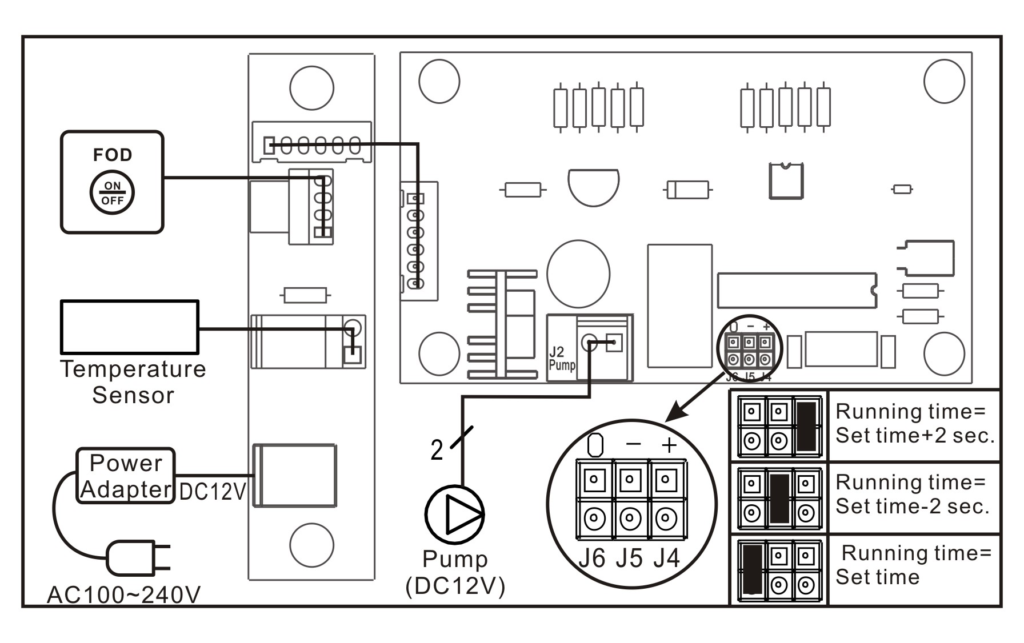

Electrical Diagram